In contemporary industrial contexts, the initial weight of machinery stands as a pivotal factor, directly shaping product design, performance metrics, and cost considerations. This article delves into the significance of the starting weight of the Smith machine in engineering and commercial decision-making, while also examining strategies for optimizing this parameter across various scenarios.

The Significance of Initial Weight

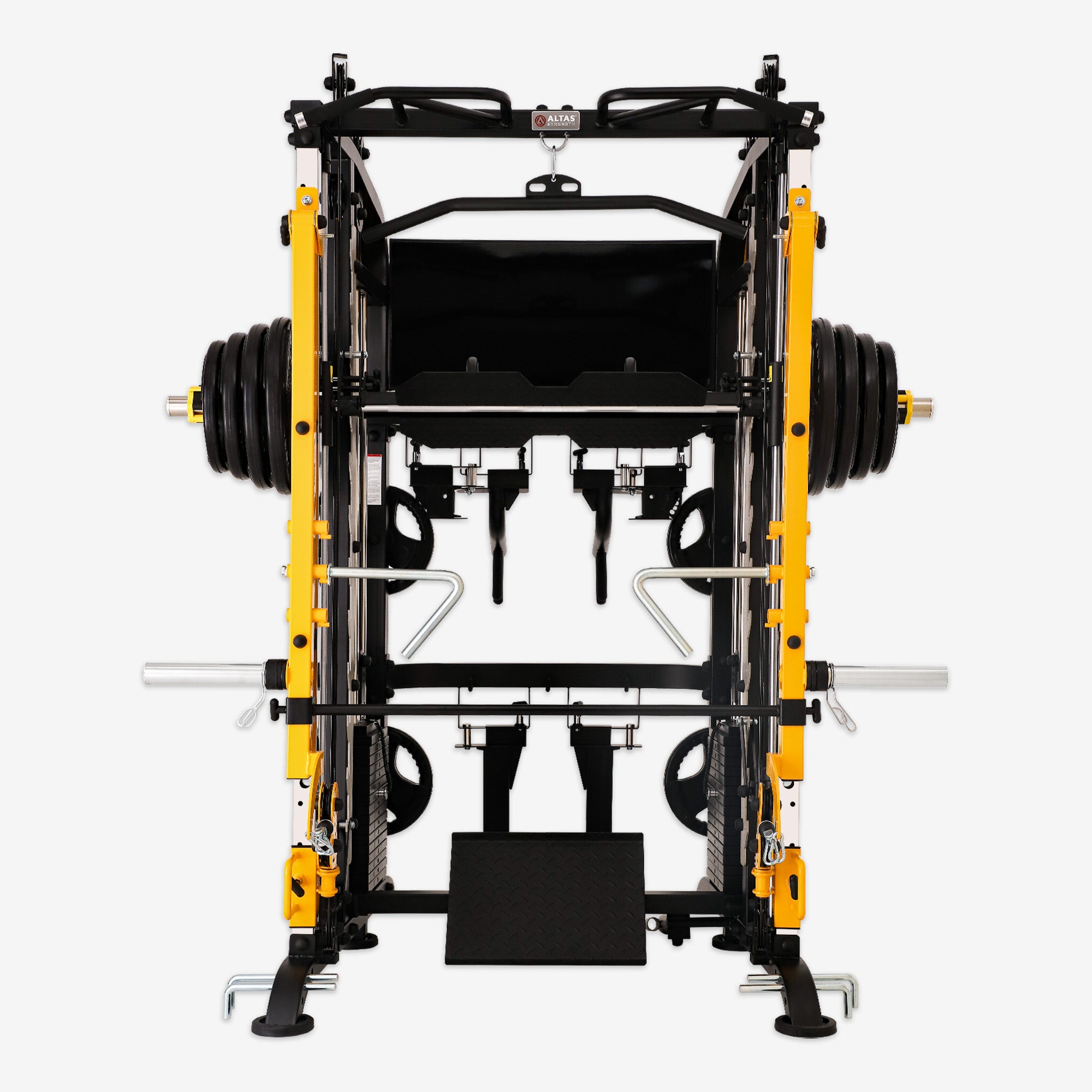

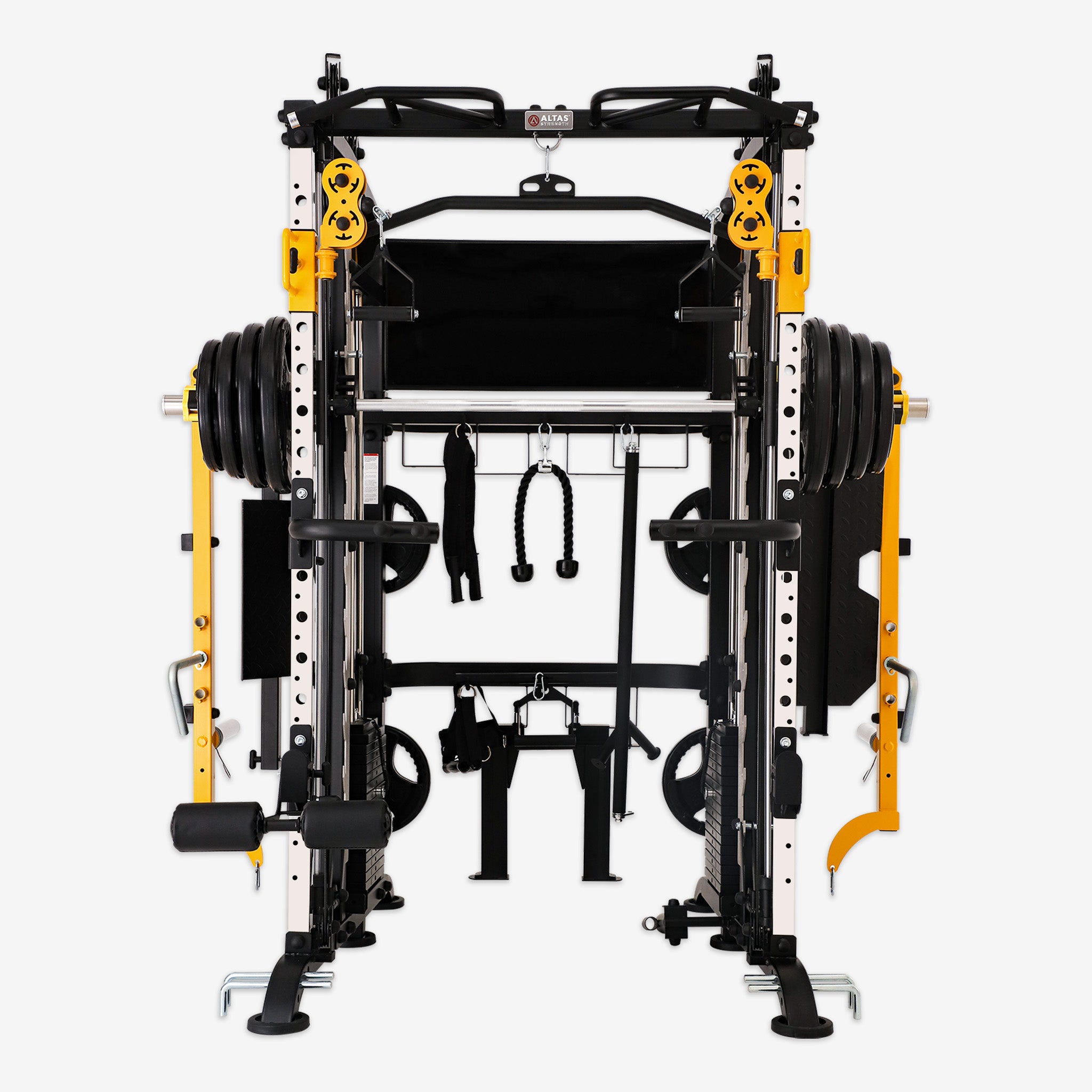

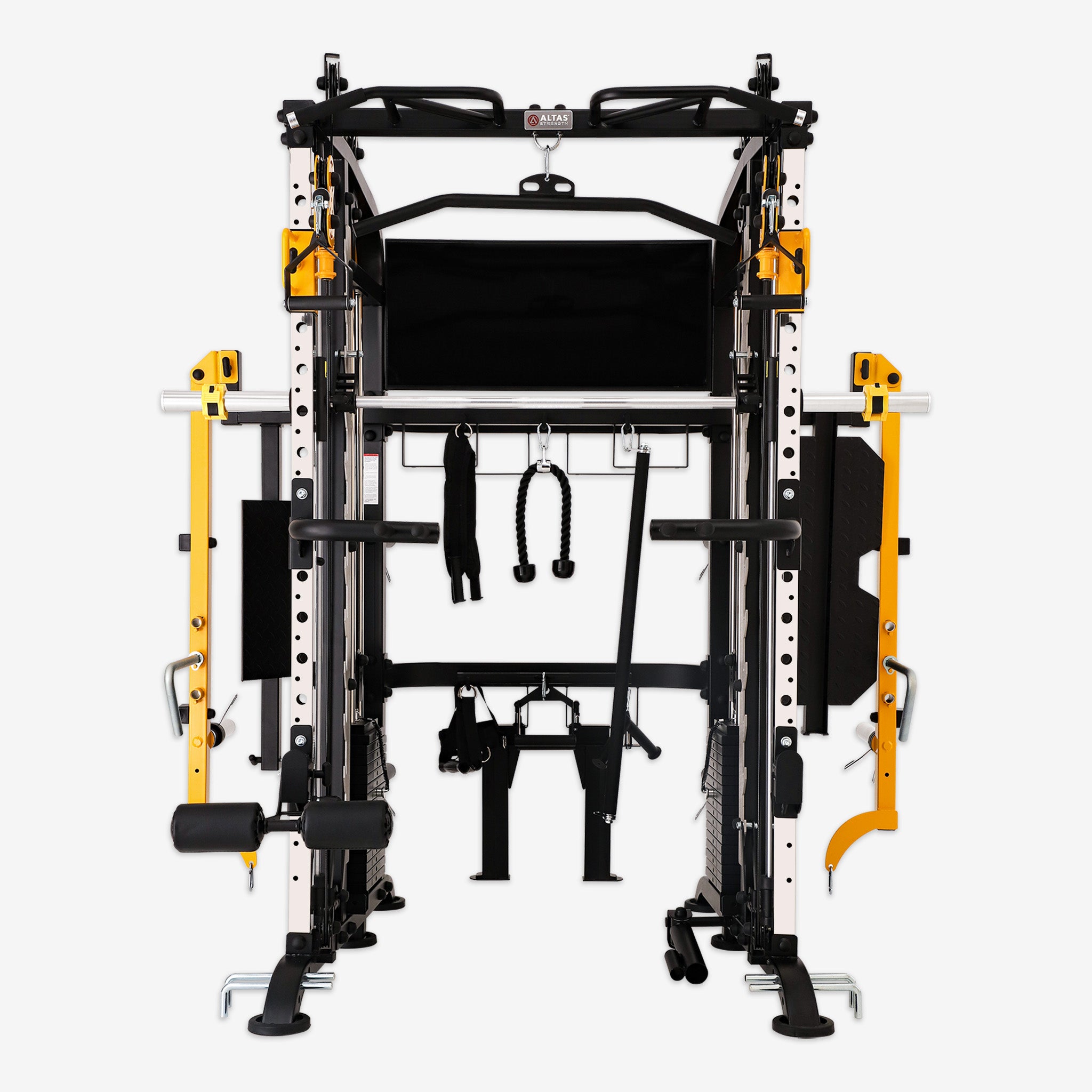

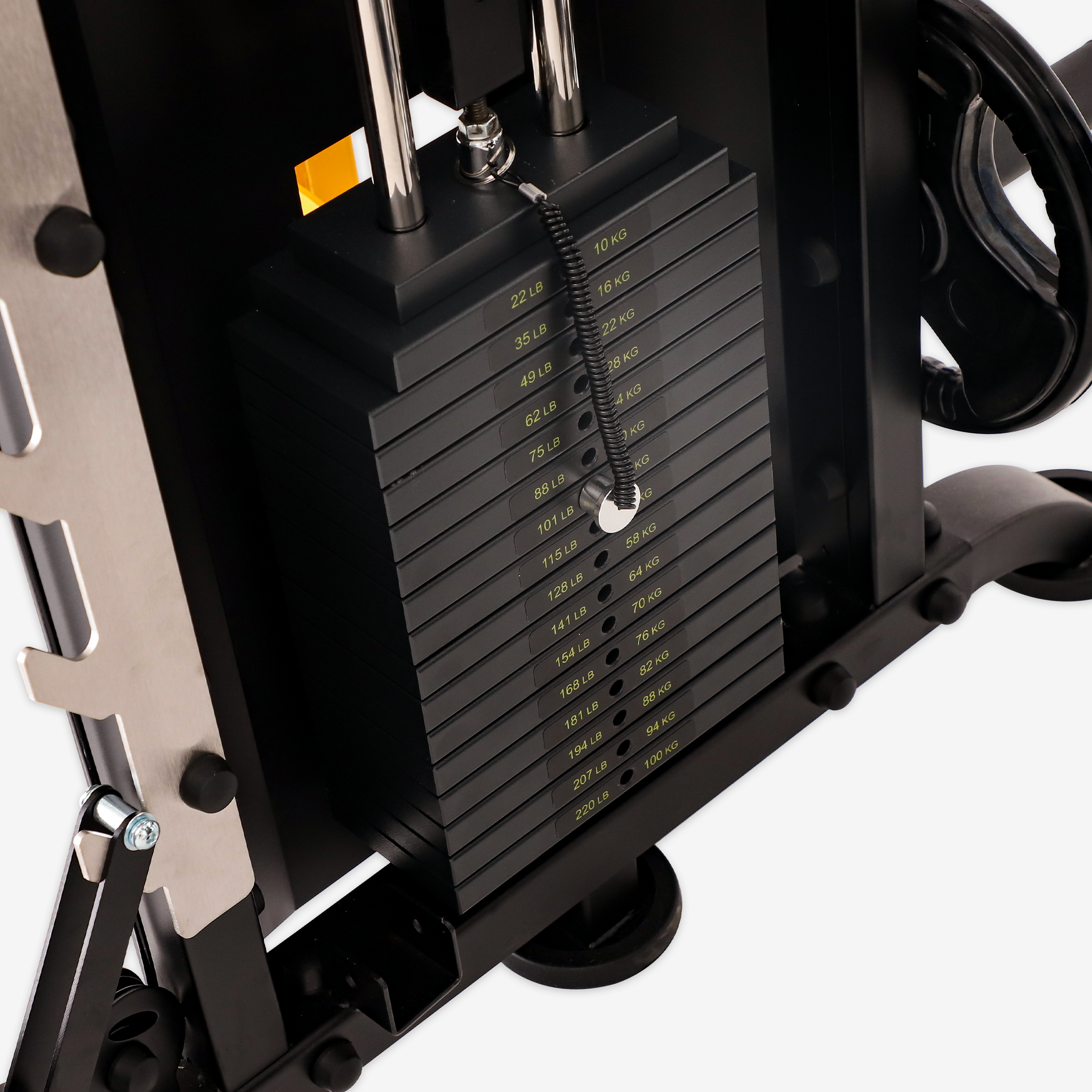

The initial weight of the Smith machine is crucial to its functionality and performance. In the realm of mechanical equipment, weight directly impacts operational efficiency, reliability, and adaptability in specific work environments. A lighter machine may facilitate easier mobility and installation, ideal for applications requiring frequent relocation or limited space. Conversely, a heavier machine may offer enhanced stability and durability, suited for prolonged operation or high-intensity tasks.

Impact on Manufacturing and Operational Costs

Furthermore, the initial weight of the Smith machine directly influences both manufacturing costs and operational expenses. During the manufacturing phase, material costs and processing complexities escalate with increasing weight. Therefore, lightweight design can to some extent mitigate initial investments. In operational phases, lighter machines may reduce energy consumption and maintenance costs, thereby lowering overall total cost of ownership (TCO).

Strategies for Weight Optimization

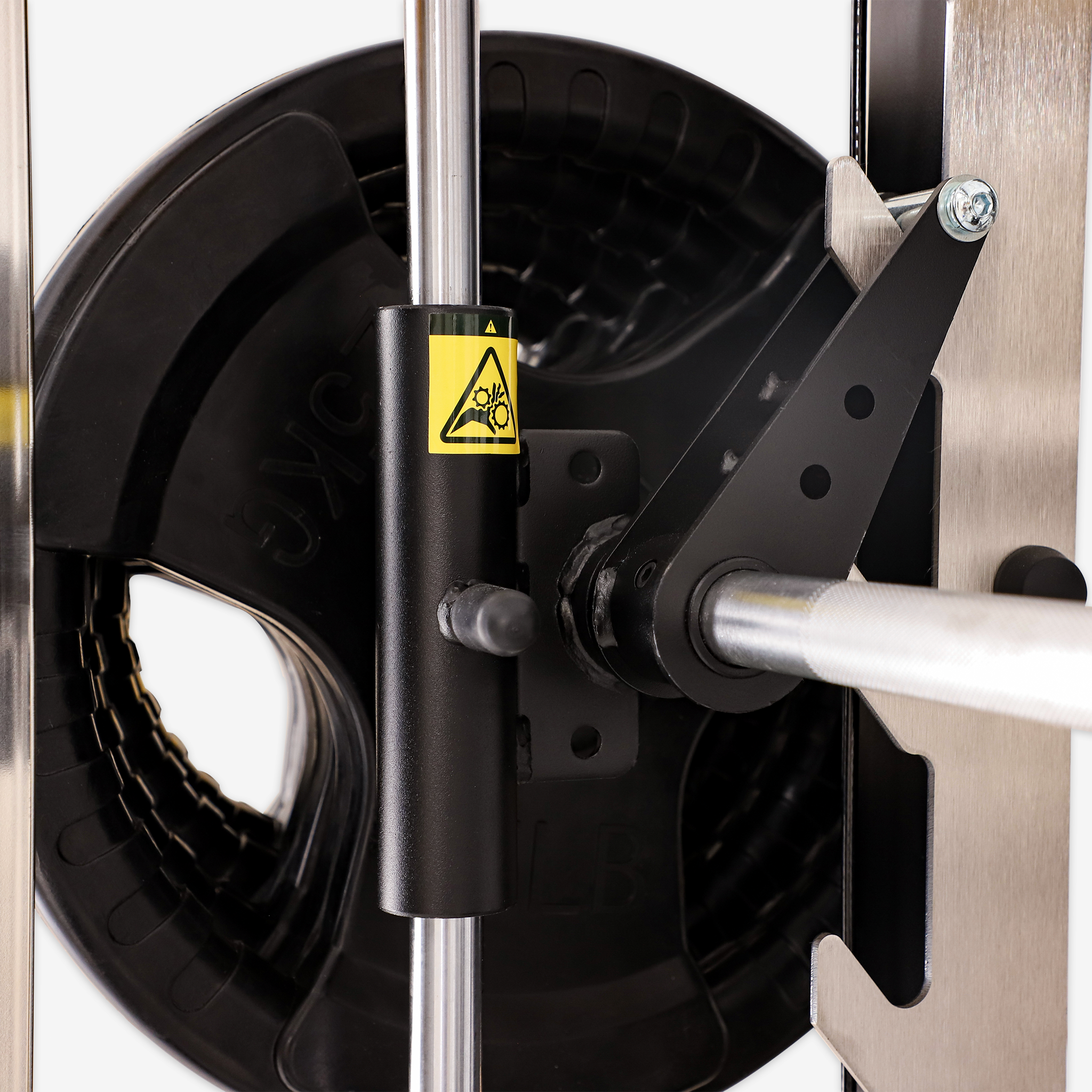

For designers and manufacturers of Smith machines, optimizing initial weight entails a comprehensive evaluation of various factors, including requirements, performance standards, material selection, and manufacturing processes. Modern engineering techniques and computational tools facilitate the feasibility of balancing and optimizing among different design alternatives, thereby achieving an optimal balance between performance and cost-effectiveness.

Conclusion: A Pivotal Factor in Competitive Market

In summary, the initial weight of the Smith machine is not merely a technical specification but a pivotal factor in engineering decisions and market competition. By comprehending and optimizing the starting weight, manufacturers can enhance product competitiveness, meet customer demands, and secure advantageous positions in the global market.

Therefore, whether in the early stages of product development or amidst the competitive landscape of the market, the initial weight of the Smith machine should be a pivotal concern subject to thorough scrutiny and strategic planning by engineers and managers alike. Through systematic analysis and comprehensive deliberation, it ensures the ultimate design meets both technical requirements and competitive market standards for Smith machines.